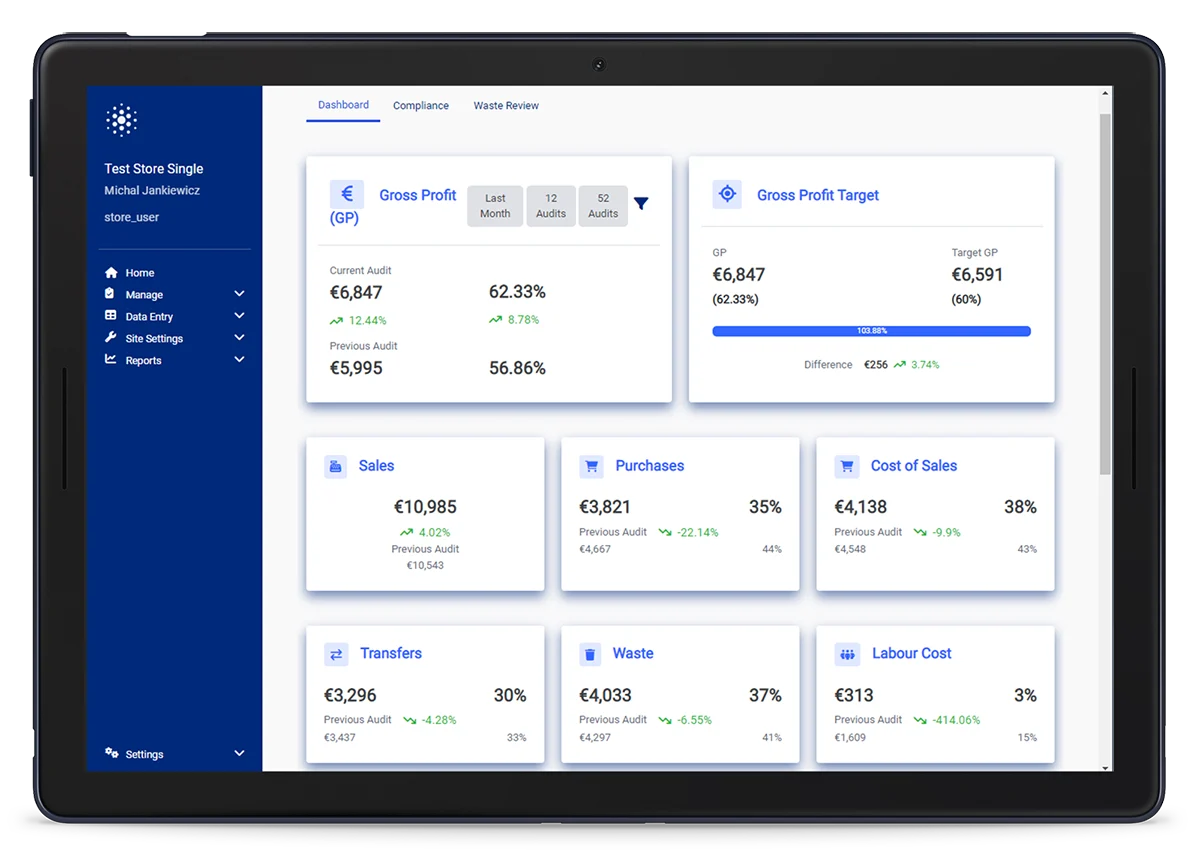

But like many food service businesses, you struggle to get a precise picture of food waste, because you can’t find a reliable system to track it.

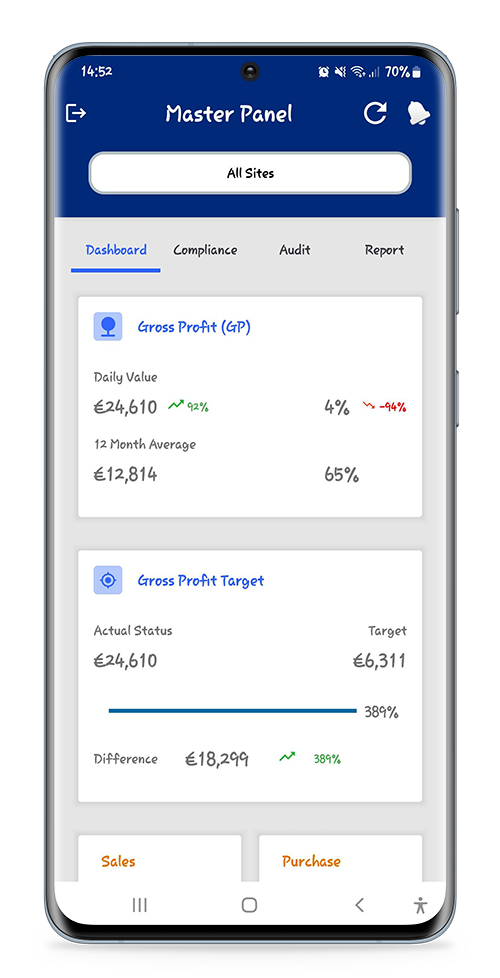

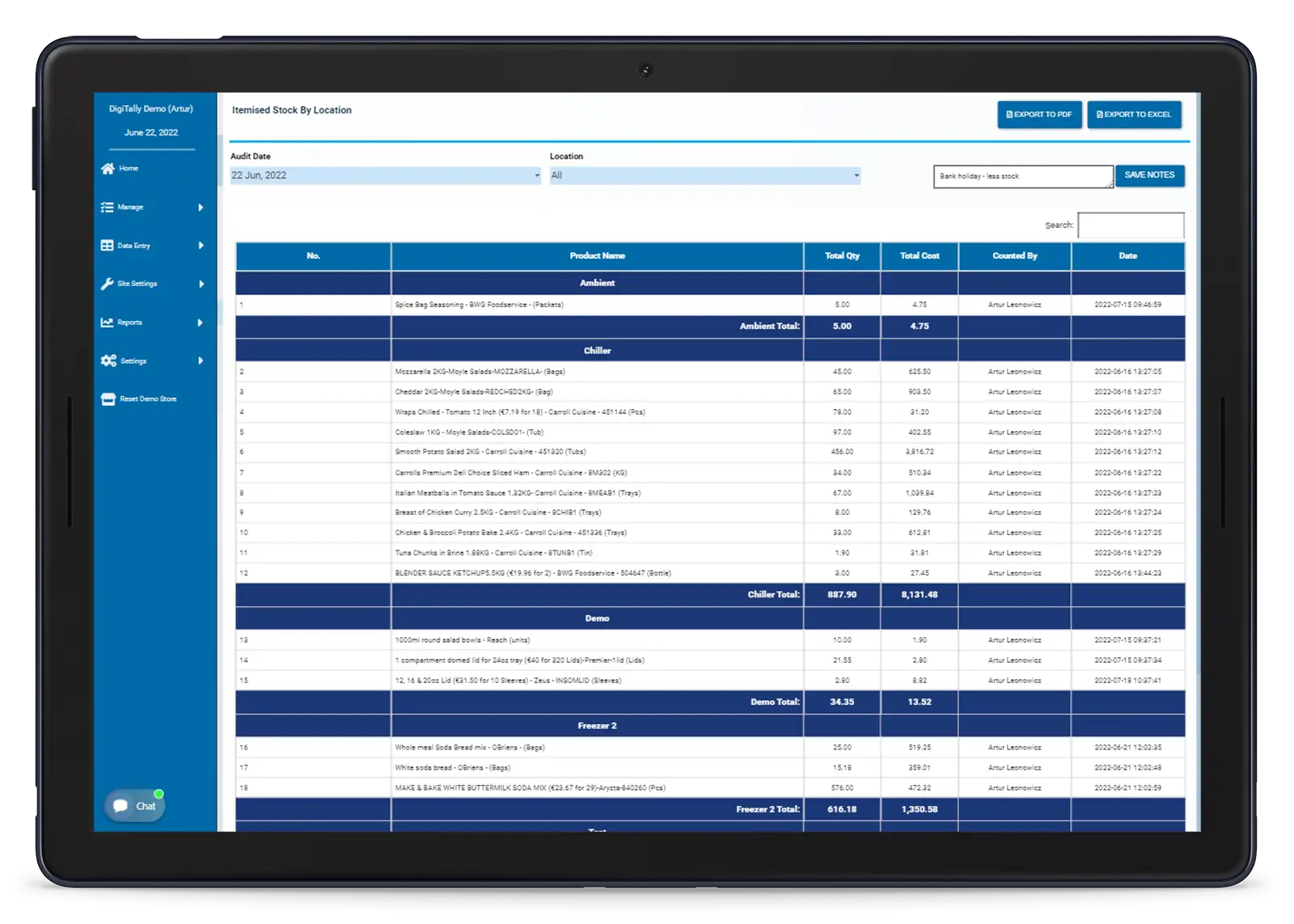

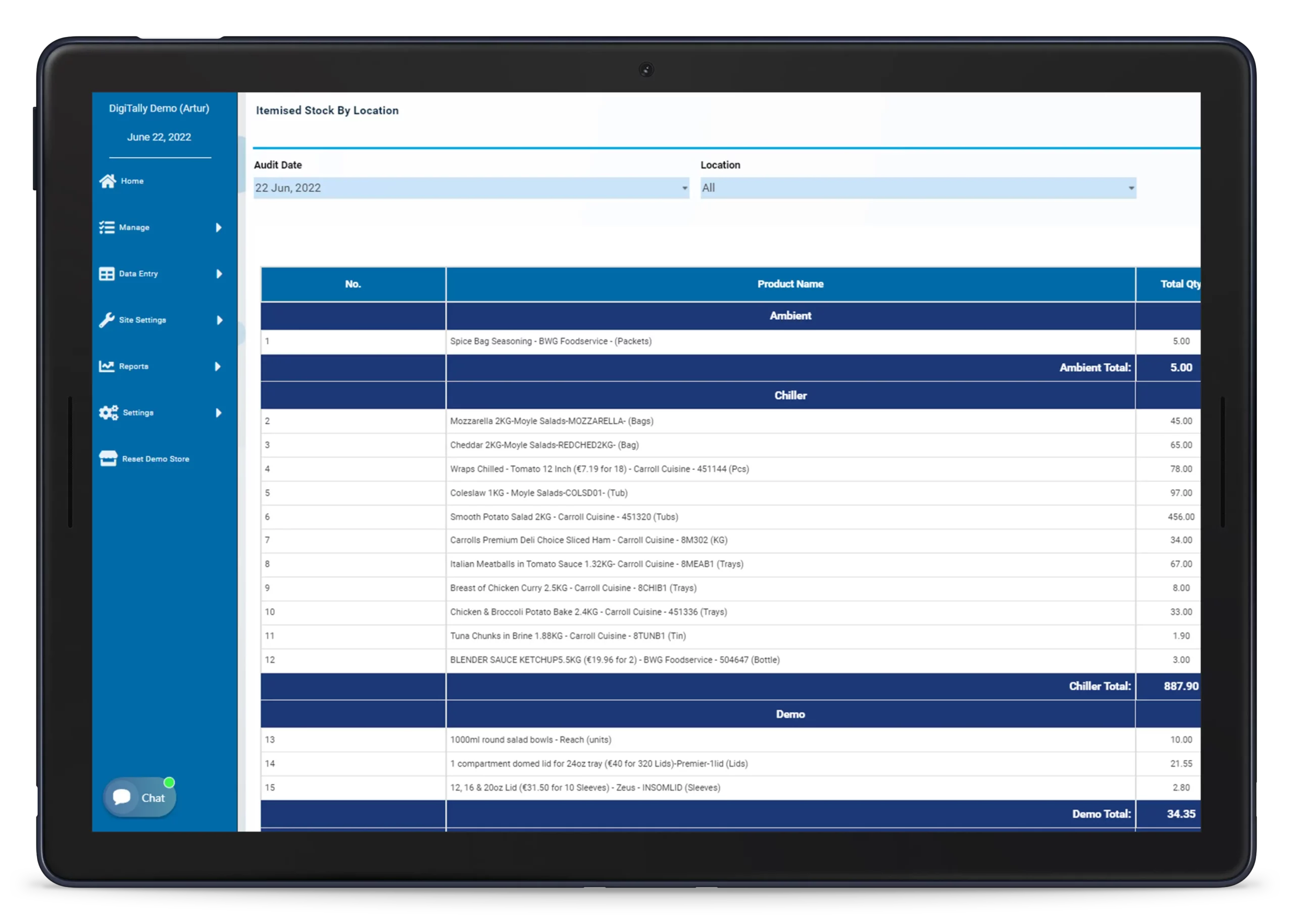

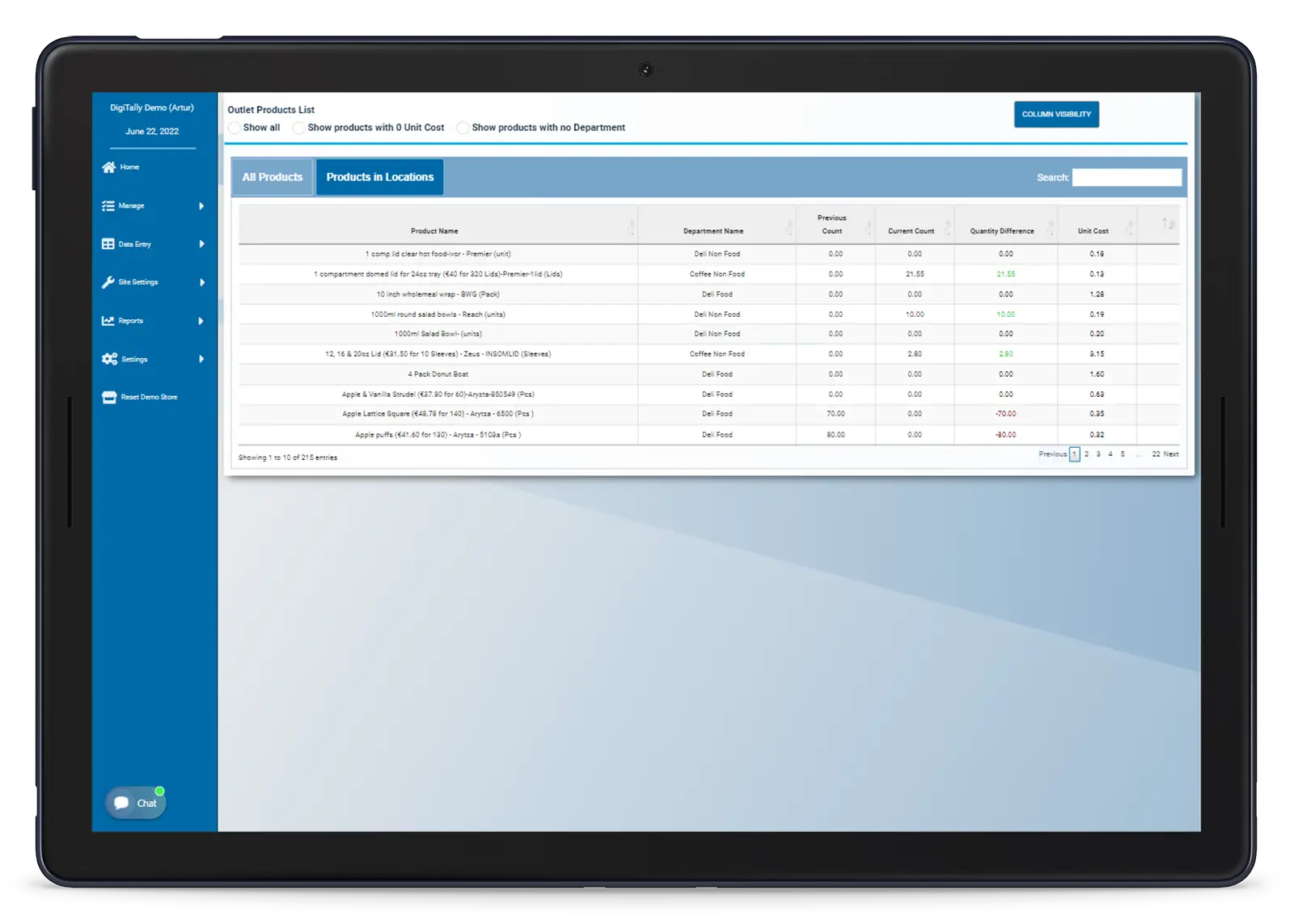

With DigiTally, you’ll know exactly what products are being wasted, why the wastage is happening and where in your business it’s occurring.

Which means you’ll be in control down to the very last crumb.